Demo Video

Demo Video

Have Questions?

Low Price Guarantee!

We know our machines!

Buy Now, Pay Later

We're in Florida!

The MF-7500 Series is a newly developed coverstitch machine provided with lots of mechanisms for improving the seam quality. It is provided with many different sewing-related mechanisms which contribute to improved seam quality, such as the new feed mechanism, and differential-feed micro-adjustment mechanism. In addition, the machine is provided as standard with a looper thread twining prevention mechanism for improved maintenance.

This Juki 3 Needle Coverstitch machine is perfect for hemming of sleeves and bottoms of t-shirts and the covering stitches for sportswear and knitwear. However, it is not a specific-purpose model, but can be used for a broad range of processes independently. Our package for this machine includes a professional table, lamp, pedal and high-quality adjustable servo motor.

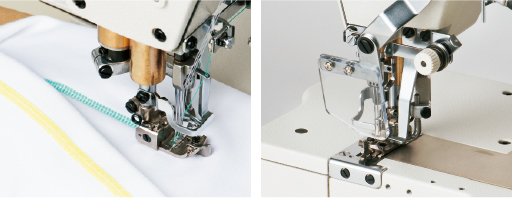

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. The front cover is trimmed to allow operators to bring their hands closer near the needle entry area, thereby increasing work efficiency in the covering process, etc.

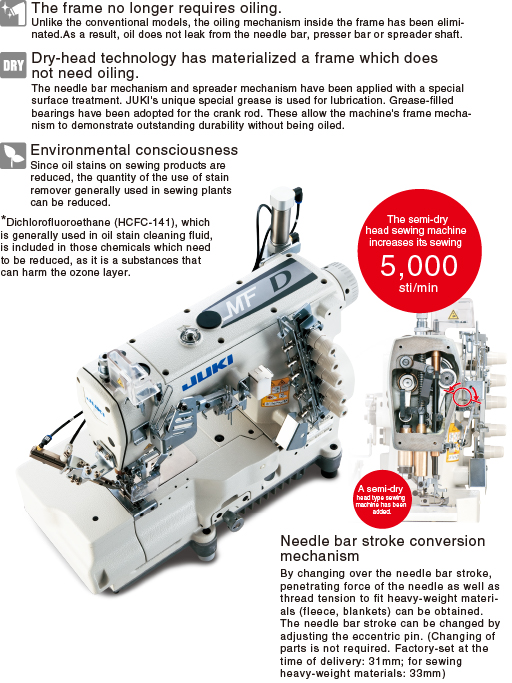

With the excellent functions inherited from the MF-7500 Series, the MF-7500D is provided with a dry frame mechanism to eliminate the cause of oil stains. Stain removing work or re-sewing work is substantially reduced by protecting sewing products from being stained with oil, thereby improving the quality of finished products.

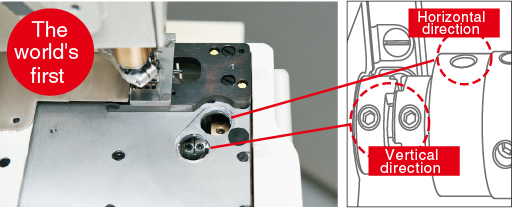

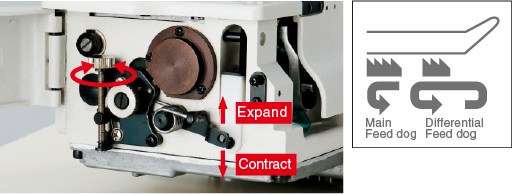

The feed locus can be adjusted externally. The feed locus is now adjustable in terms of the vertical direction and horizontal direction, thereby improving responsiveness to sewing materials.

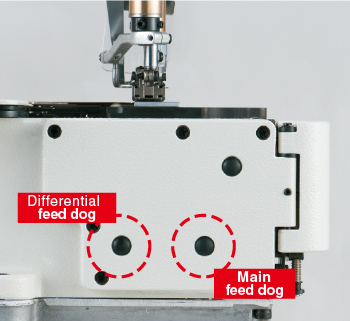

The longitudinal position of the feed is adjustable. As a result, uneven material feed and puckering that are likely to occur when sewing products made of elastic materials such as foundations are reduced. This means that the machine promises improved responsiveness to elastic materials.

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. The differential feed ratio is constant even if the stitch length is changed.

Elastic material or delicate material can be sewn with the presser foot kept slightly raised. This effectively helps reduce the degree of slippage, warpage and damage of the material.

In the case of looper thread breakage, the looper thread twining prevention mechanism is activated to trim the looper thread before the thread twines on the looper thread cam. In this way, the looper thread twining prevention mechanism prevents the looper thread from twining on the looper thread cam. In addition, the looper thread cam, which has been incorporated in the sewing machine, has been changed so that it is mounted outside of the sewing machine. The externally-mounted looper thread cam promises improved maintainability.

As a result of the commonality of components, commercially-available components (presser foot, throat plate and needle clamp) are now applicable and easily obtainable. Visit https://parts.jacksew.com/ to order Juki Original gauge parts.

No Looper thread Twining

The rotating part of the looper thread camshaft is covered to prevent the looper thread from twining around the looper thread camshaft. A V-shaped thread catcher has been installed on the looper thread cam bracket to easily clamp the looper thread, which is likely to twine around the cam.

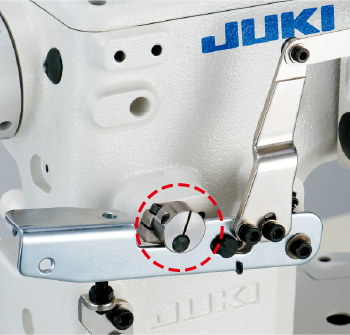

Needle Bar Stroke Conversion Mechanism

By changing over the needle bar stroke, penetrating force of the needle as well as thread tension to fit heavy-weight materials (fleece, blankets) can be obtained. The needle bar stroke can be changed by adjusting the eccentric pin. (Changing of parts is not required. Factory-set at the time of delivery: 31mm; for sewing heavy-weight materials: 33mm) Micro-Lifter Mechanism Elastic material or delicate material can be sewn with the presser foot kept slightly raised. This effectively helps reduce the degree of slippage, warpage, and damage to the material.

Stitch Type Change Over

It is now possible to change the stitch type, such as elastic soft-seams for innerwear and high-quality well-tensed seams for outerwear. The stitch type can be changed over (soft-seams/well-tensed seams) simply by changing the thread path.

Differential-feed Micro-adjustment Mechanism

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. The differential feed ratio is constant even if the stitch length is changed Feed Dog Inclination Adjustment The feed dog inclination can be externally adjusted with ease. This adjustment mechanism effectively helps improve the material holding ability of the feed dog and prevent uneven material feed and puckering.

Thanks to the speed control feature, most users find the machine easier to use. Both beginner and advanced sewers find this feature helpful when stitching projects that require high-speed and precise stitching.

Besides any applicable warranties provided by the Original Manufacturer, Jacksew offers a standalone 90-day limited warranty on defects in materials and workmanship.

This warranty covers all the machine parts and labor but any shipping costs must be covered by the customer

Only applies under normal sewing conditions as prescribed for the machine

Consumable items are not covered (needles, bobbins, bobbin cases, springs, oil, and belts)

This warranty does not cover improper use or abuse under heavy use of machines

This warranty does not cover flood, fire, or other acts of nature

If there are any warranty issues that arise, we ask that you contact us immediately and let us know the details. In most cases, we can guide you with getting your machine in good sewing condition via phone, text or video chat.

If you need any parts that need to be replaced, we stock the majority of parts for immediate shipment. Some parts not in stock may have to be ordered from the manufacturer and may take 1 to 2 weeks for arrival.

If there is a critical issue that needs to be addressed and is out of scope of minor adjustments or repairs, we will ask you to send us the machine to our shop so we can have it repaired and have it back to good sewing condition. In most cases, we will only need the machine head shipped to us. Shipping charges - both inbound and outbound - are the responsibility of the customer.

Warranty issues do not arise frequently because of our commitment to assemble, test and verify each machine we ship out to our customers. We will never send you a machine directly from the manufacturer in boxes without knowing that the machine will be ready to operate upon arrival.

DISCLAIMER: DUE TO THE HEAVY WEIGHT AND SHIPPING METHODS USED FOR INDUSTRIAL MACHINES THEY MAY EXPERIENCE MARRING AND SCRATCHES DURING SHIPPING. THIS WILL NOT AFFECT THE OPERATION OF THE MACHINE.

ANY DAMAGE OCCURRING DURING SHIPPING MUST BE CLAIMED TO THE FREIGHT CARRIER IMMEDIATELY. UPON REQUEST, JACKSEW WILL PROVIDE ASSISTANCE IN FILING A CLAIM ON YOUR BEHALF DURING SUCH AN EVENT. PLEASE NOTIFY US WITHIN 5 BUSINESS DAYS.