Have Questions?

Low Price Guarantee!

We know our machines!

Buy Now, Pay Later

We're in Florida!

Also available in 2-Needle LU1560N-7

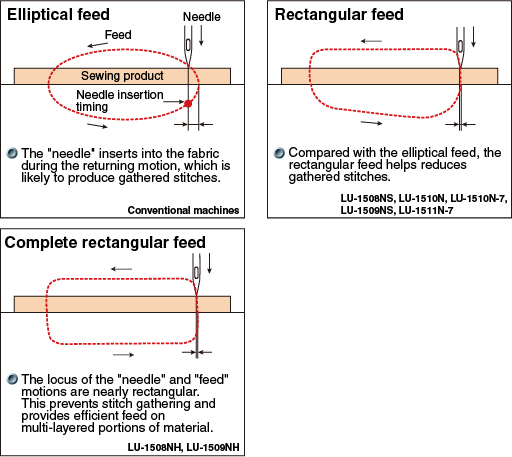

The maximum stitch length is 10mm. The complete rectangular feed locus enables accurate feed of extra heavy materials while preventing stitch gathering. With its sufficient needle-bar stroke of 38mm and long 190R needle, the machine supports the sewing of extra heavy materials. The machine comes with an extra large steel hand-wheel with a diameter as large as φ175.

The new mechanism with a rectangular feeding motion promises consistent feed of materials of all thickness without stitch gathering. The lower orbit of the feed dog prevents the material from flopping and reduces operating noise and vibration.

With the adoption of a new rectangular feed mechanism, an alternating vertical movement mechanism, and a unison feed mechanism, the machine can feed heavy materials powerfully and smoothly. Well tensed seams are consistently produced without pitch errors.

With its maximum stitch length of 9mm, the machine can be applied to a broader range of uses.

The 1-needle type machine has adopted a dual-tension mechanism, with which the machine can support high-tension sewing with thick thread. This means that the machine produces seams of excellent quality on a broader range of materials, extending from light- to heavy-weight.

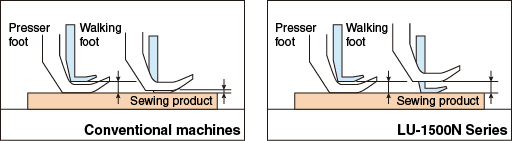

The machine has adopted a new mechanism that does not change the ratio of alternate vertical movement of the walking foot and presser foot even when the material thickness changes.

Even when a heavy-weight material is used, the presser foot lift does not decrease. This means that the presser foot comes into contact with the material at exactly the same time that it does when sewing lighter-weight sections of the material. As a result, the walking foot retains the material with a consistent pressure to prevent irregular stitches.

The amount of the alternating vertical movement of the walking foot and presser foot can be adjusted up to the maximum of 6.5mm according to the height of multilayered portions of material.

The high, 16mm foot lift enables easy material handling.

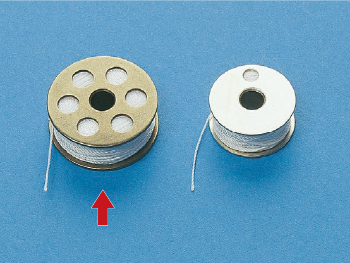

With the adoption of this vertical-axis double-capacity hook, the frequency of bobbin thread changing is reduced, promising sewing work of increased efficiency.

The stitch length can be easily selected by the stitch dial.

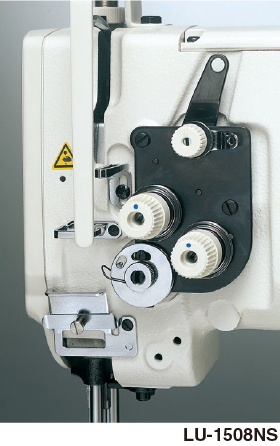

The machine is provided with many improved features that offer enhanced operability such as an easy-to-observe area around the needle, placement of the bobbin winder on the front face of the machine arm, and a large handwheel (φ160).

Since the needle thread tension-release solenoid is fitted on the rear face of the machine head, the area around the needle entry and one-touch type reverse feed button is easily viewable. This substantially contributes to improved operability.

The machine leaves a shorter needle thread after thread trimming, improving thread consumption efficiency. With a rigid knife and improved cam shape, the thread trimmer cuts thread as thick as #5 without fail.

The 1-needle type machine is equipped with a bottom-feed micro-adjustment mechanism with the needle feed amount fixed. This helps prevent irregular stitches which are free from pitch errors.

Thanks to the speed control feature, most users find the machine easier to use. Both beginner and advanced sewers find this feature helpful when stitching projects that require high-speed and precise stitching.

Besides any applicable warranties provided by the Original Manufacturer, Jacksew offers a standalone 90-day limited warranty on defects in materials and workmanship.

This warranty covers all the machine parts and labor but any shipping costs must be covered by the customer

Only applies under normal sewing conditions as prescribed for the machine

Consumable items are not covered (needles, bobbins, bobbin cases, springs, oil, and belts)

This warranty does not cover improper use or abuse under heavy use of machines

This warranty does not cover flood, fire, or other acts of nature

If there are any warranty issues that arise, we ask that you contact us immediately and let us know the details. In most cases, we can guide you with getting your machine in good sewing condition via phone, text or video chat.

If you need any parts that need to be replaced, we stock the majority of parts for immediate shipment. Some parts not in stock may have to be ordered from the manufacturer and may take 1 to 2 weeks for arrival.

If there is a critical issue that needs to be addressed and is out of scope of minor adjustments or repairs, we will ask you to send us the machine to our shop so we can have it repaired and have it back to good sewing condition. In most cases, we will only need the machine head shipped to us. Shipping charges - both inbound and outbound - are the responsibility of the customer.

Warranty issues do not arise frequently because of our commitment to assemble, test and verify each machine we ship out to our customers. We will never send you a machine directly from the manufacturer in boxes without knowing that the machine will be ready to operate upon arrival.

DISCLAIMER: DUE TO THE HEAVY WEIGHT AND SHIPPING METHODS USED FOR INDUSTRIAL MACHINES THEY MAY EXPERIENCE MARRING AND SCRATCHES DURING SHIPPING. THIS WILL NOT AFFECT THE OPERATION OF THE MACHINE.

ANY DAMAGE OCCURRING DURING SHIPPING MUST BE CLAIMED TO THE FREIGHT CARRIER IMMEDIATELY. UPON REQUEST, JACKSEW WILL PROVIDE ASSISTANCE IN FILING A CLAIM ON YOUR BEHALF DURING SUCH AN EVENT. PLEASE NOTIFY US WITHIN 5 BUSINESS DAYS.