Have Questions?

Low Price Guarantee!

We know our machines!

Buy Now, Pay Later

We're in Florida!

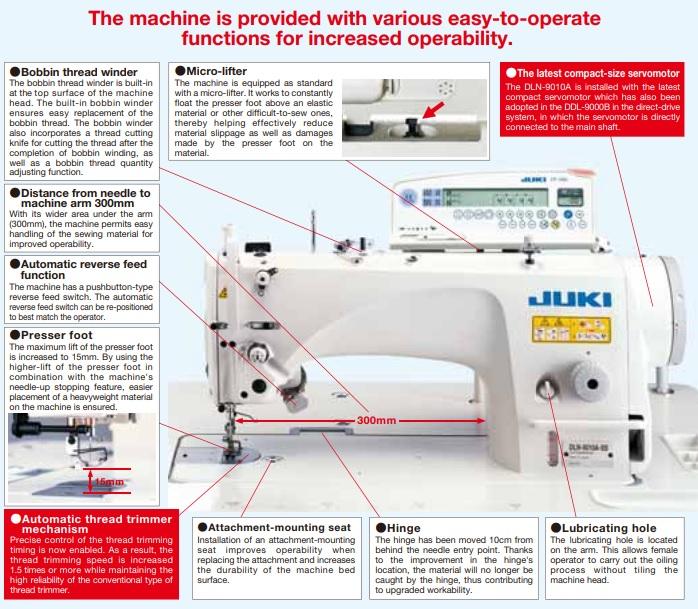

The JUKI DLN-9010A-SH is a needle-feed type DDL-9000 Series sewing machine which is JUKI's top-of-the-line lockstitch machine series with a thread trimmer.

It has inherited the exceptional features of the DDL-9000 Series, such as the direct-drive system, semi-long arm and elimination of the oil pan. Also, it comes with a highly reliable needle feed mechanism.

The needle feed mechanism, which is widely recognized as offering outstanding efficiency of feed and effectively preventing uneven material feed, responds to a wide range of applications such as the sewing of outerwear, runstitching of men's shirts, etc. and the attaching of various parts to garment bodies.

The machine has been configured to eliminate the oil pan, and supplies a minute quantity of lubricating oil to the hook and needle bar, thereby contributing to the reation of a clean work environment.

The machine saves you the time and trouble of removing the knee-lifter and cover. This means that the machine head can be tilted for cleaning and maintenance without the inconvenience of removing the knee-lifter and cover.

Even if you tilt the machine head while the power is still ON, the safety switch will disable the machine. This means the machine won't start running when the head is tilted even if you press the foot pedal.

The new model control box SC-920A, which consists of an energy-saving mode, has been developed. This control box is the first one which provides an energy-saving mode for the sewing machine. The power consumption during standby, when the motor is at rest, is reduced by approximately 20%.

Two different operation panels, the CP-18A and CP-180A are applicable to the DLN-9010A. Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes)

Thanks to its most advanced compact AC Servo motor, as well as employing the new model control box SC-920A, the DLN-9010A achieves a substantial labor-saving equivalent to that of the DDL-9000B.

The thread trimming speed is increased 1.5 times or more as compared with the conventional model, as the thread trimming timing can now be precisely controlled.

The needle feed mechanism offers exceptional efficiency of feed and effectively preventing uneven material feed, on a wide range of applications such as the sewing of outerwear, run stitching of men's shirts, etc. and the attaching of various parts to garment bodies.

This machine comes with a JUKI CP-18 operation panel, with an option to upgrade to a JUKI CP-180 operation panel. (**product photo shows a CP-180 operation panel)

1 The maximum sewing speed is 4,000 stitches per minute or less in cases where the maximum stitch length is 3.5mm or more.

Thanks to the speed control feature, most users find the machine easier to use. Both beginner and advanced sewers find this feature helpful when stitching projects that require high-speed and precise stitching.

Besides any applicable warranties provided by the Original Manufacturer, Jacksew offers a standalone 90-day limited warranty on defects in materials and workmanship.

This warranty covers all the machine parts and labor but any shipping costs must be covered by the customer

Only applies under normal sewing conditions as prescribed for the machine

Consumable items are not covered (needles, bobbins, bobbin cases, springs, oil, and belts)

This warranty does not cover improper use or abuse under heavy use of machines

This warranty does not cover flood, fire, or other acts of nature

If there are any warranty issues that arise, we ask that you contact us immediately and let us know the details. In most cases, we can guide you with getting your machine in good sewing condition via phone, text or video chat.

If you need any parts that need to be replaced, we stock the majority of parts for immediate shipment. Some parts not in stock may have to be ordered from the manufacturer and may take 1 to 2 weeks for arrival.

If there is a critical issue that needs to be addressed and is out of scope of minor adjustments or repairs, we will ask you to send us the machine to our shop so we can have it repaired and have it back to good sewing condition. In most cases, we will only need the machine head shipped to us. Shipping charges - both inbound and outbound - are the responsibility of the customer.

Warranty issues do not arise frequently because of our commitment to assemble, test and verify each machine we ship out to our customers. We will never send you a machine directly from the manufacturer in boxes without knowing that the machine will be ready to operate upon arrival.

DISCLAIMER: DUE TO THE HEAVY WEIGHT AND SHIPPING METHODS USED FOR INDUSTRIAL MACHINES THEY MAY EXPERIENCE MARRING AND SCRATCHES DURING SHIPPING. THIS WILL NOT AFFECT THE OPERATION OF THE MACHINE.

ANY DAMAGE OCCURRING DURING SHIPPING MUST BE CLAIMED TO THE FREIGHT CARRIER IMMEDIATELY. UPON REQUEST, JACKSEW WILL PROVIDE ASSISTANCE IN FILING A CLAIM ON YOUR BEHALF DURING SUCH AN EVENT. PLEASE NOTIFY US WITHIN 5 BUSINESS DAYS.