Have Questions?

Low Price Guarantee!

We know our machines!

Buy Now, Pay Later

We're in Florida!

A state-of-the-art sewing system that revolutionizes the perfection for “sewing”. Succeeding the traditionally required experience and instincts, digitalized setting capability in JUKI’s all new DDL-9000C digital sewing system presents the best sewing conditions everywhere and anywhere.

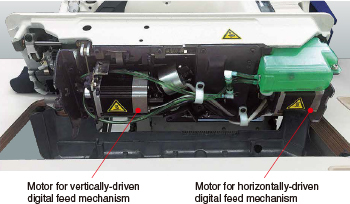

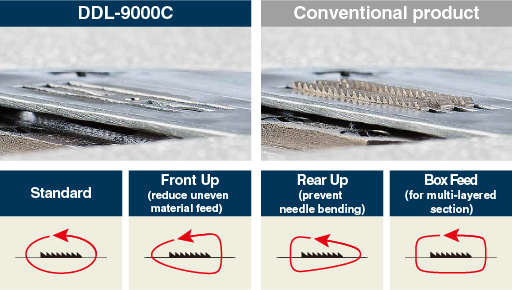

Thanks to the world’s first vertically-and horizontally-driven digital feed mechanism, the feed dog height can be adjusted with ease according to the material fabric of product to be sewn, thereby improving seam quality.

Thanks to this digital feed mechanism, thread trimming is carried out with the feed dog lowered in the case the shorter-thread remaining thread trimming function is enabled. As a result, the clearance provided between the throat plate and the material is eliminated, thereby stabilizing the length of thread remaining after thread trimming. The feed dog does not protrude the top surface of throat plate when the sewing machine stops with its needle bar up, thereby facilitating placement/removal of the material on/from the top surface of throat plate and preventing the material from being damaged by the feed dog.

Two different modes; i.e., the operator mode which prioritize ease of operation and the serviceperson mode, are prepared to respectively display indications according to the user.

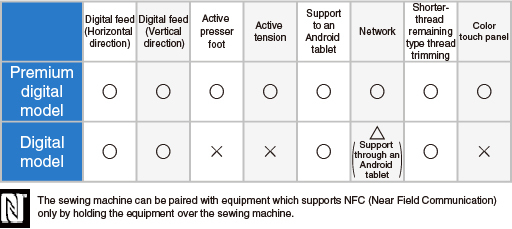

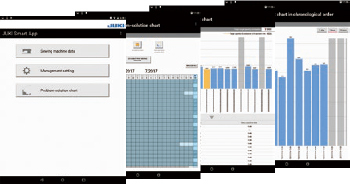

In addition, installation of NFC enables data transfer to an Android tablet. Data transferred from the sewing machine to an Android tablet can be edited on the tablet.

In the application, there are items of management setting (terminal registration), sewing machine data (sewing data), problem-solution chart. In the problem-solution chart, we can generate production graphs, the availability chart, etc. for each acquired sewing machine data so it can be used for checking the current situation and analyzing it.

*Android OS Version 6.0 is recommended to use JUKI Smart APP.

(Operation is confirmed with respect to Versions 5.0 and later.)

Contact JUKI distributor in your area for how to use the application software.

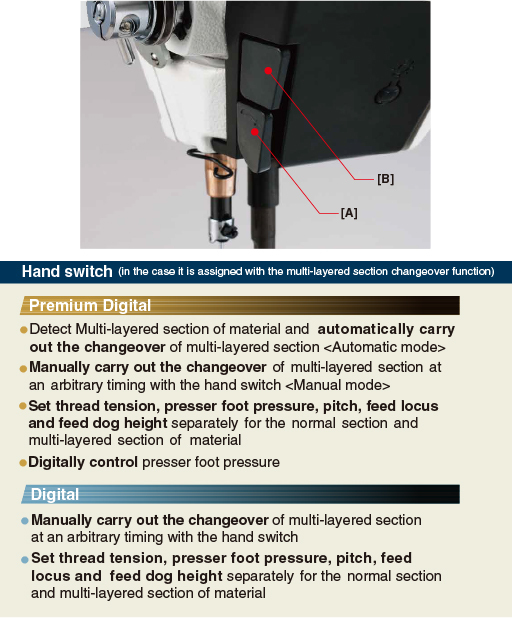

Digital control system controls the presser foot pressure. Under the automatic mode, the multi-layered section detection function detects changes in material thickness to increase/decrease the presser foot pressure accordingly.

Under the manual mode, the presser foot pressure control function is assigned to the hand switch to enable operation with the hand switch.

The active presser foot pressure mechanism demonstrates its effectiveness in prevention of stitch gathering and loose stitches.

The needle thread tension, presser foot pressure, pitch, feed locus and feed dog height can be totally changed to link their adjustments appropriately.

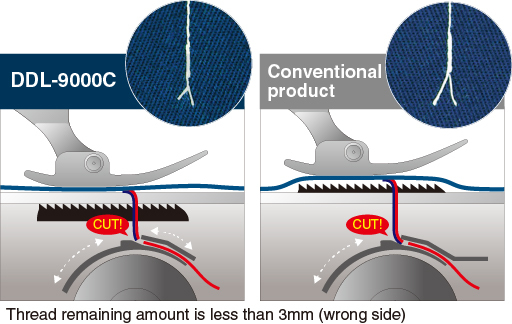

Newly adopted “double digital feed mechanism” controls up/down of the feed dog and the “double-edge driving rotary knife system” allows the feed dog to come down at the time of trimming the thread.

As a result, the knives intersect with each other just under the needle entry point.

This mechanism not only ensures the needle thread length of 3 mm or less that trails from the needle eyelet after thread trimming without being affected by the stitch length but also allows the operator to place/remove the material on/ from the sewing machine with ease.

Newly-developed auto-lifter device comes with a stepping motor. This not only increases the amount of lift of the presser foot from 8.5 mm to 13.5 mm at the maximum but also reduces the operating noise.

After the thread cutting of the sewing machine, thanks to the feature of the world's first top and bottom drive electronic feed mechanism to prevent the feed dog from protruding the top of throat plate, the material can be placed under presser foot and removed from there with ease and is not easily damaged.

*To lift the presser foot to its maximum amount of lift, it is necessary to set the amount of lift in two stages.

*For the full-digital type model, the auto-lifter function is provided as standard.

Digitalized vertically- and horizontally-driven feed mechanism allows easy adjustment of settings such as the feed locus only on the operation panel according to the material to be sewn.

The device clamps the needle thread and draws it under the material at the beginning of sewing. The needle thread clamp device works to reduce the size of thread tangling in on the wrong side of the material.

This expands the area around the needle entry, thereby allowing the use of various gauge components.

Functions of two hand switches can be set through the operation panel. Since the reverse-feed stitching lever is provided as standard, added functions can be customized. 20 different functions (needle-up/ down correction sewing, everse-feed correction sewing, 1-time reverse-feed stitching cancellation function, etc.) are available. Highly convenient operation is enabled by setting the functions which match the sewing process in combination.

The hand switches have been factory-assigned respectively with [Α] “Touch-back switch” and [Β] “Custom switch” (to be set by the customer) at the time of shipment. The customer may assign other functions to these two hand switches.

The LED light illuminates the needle entry area in the just-under direction from the right and left sides of the needle bar. In comparison with the single-direction illumination, this LED light helps the operator carry out sewing more easily.

Illuminance of the LED light is adjustable in five levels.

It can also be used as an auxiliary lamp for working.

Thanks to the speed control feature, most users find the machine easier to use. Both beginner and advanced sewers find this feature helpful when stitching projects that require high-speed and precise stitching.