Demo Video

Demo Video

Have Questions?

Low Price Guarantee!

We know our machines!

Buy Now, Pay Later

We're in Florida!

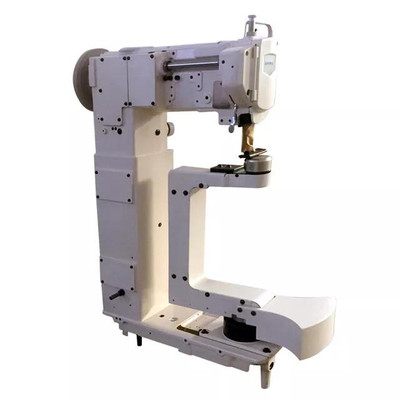

Foldable pattern field machine 140x95cm, with 360 degree rotating needle bar for perfect curved seams in all directions. Double screw transmission type. Programmable on the machine or remotely from PC.

The needle bar and the hook can rotate infinitely in sync, keeping the stitches always in the same direction, always resulting in perfect curves and corners.

It can be used for Heavy Duty materials such as automotive, marine, and airplane upholstery.

Sewing area 140x95cm, however, thanks to the folding and sliding side and front tables, it is possible to reduce the overall dimensions in 1 minute and transport it very easily without having to disassemble it.

The quick buttons allow you to quickly activate the most used functions: emergency stop, air cleaning, descent of the template clamps and start of sewing.

Thanks to the simple and intuitive interface, it is possible to create programs from the display or via PC software and import them via USB or wifi with IOT.

The smart foot stays down longer, waiting for the needle to rise to prevent the stitches from skipping and breaking. It is also possible to set different heights in different seam sections.

The radio frequency reads magnetic disks where it is possible to save the sewing design countless times. When you bring the template closer, the reader will automatically change the drawing.

Thanks to the emulation and dynamic balance analysis software, it was possible to increase the absorption of vibrations, now the resonance point of the entire machine is 1400r / min.

Improves transmission accuracy, reduces vibration and improves seam stability. The tracks with recirculating ball slide where the Y axis slides prevent dust and thread remnants from settling, reducing fluidity.

Automatic bobbin change, laser cutting grazing the seam, fine bobbin raising to avoid sewing empty and nib to mark precise points where to attach pockets or other processes are available.

Edit parameters, view statistics, send sewing designs from App / WebApp directly to the machine in the cloud wherever you are.

The machine comes fully crated with steel reinforced crating. We ship from Clearwater, Florida and can deliver to anywhere US-wide. For Canada or Mexico shipping, please contact us prior to placing your order at +1 (727) 335-3434.

Suitable for the production of quilted jackets or upholstery elements, also automotive and marine. Template can be adjusted to any element, depends on sewing pattern. Enables patterns programming on the touch control panel and storing them in memory – up to 999 patterns. The editing of already existing as well as already programmed patterns. Control panel with USB port allows importing designs from other devices (supports .dst, .dxf, .vdt files).

Serial equipped with automatic thread trimmer, air blower that works similar as wiper, safety switch and thread breaking detection. Machine with Direct Drive system with servo motor mounted in machine head and built-in fast and precise stepping motors working in X and Y axis driven by screw system. This new design and new solution of screw system create more stability of arm/rail movement on this machine.

PDS Software for pattern making is also included on the SET of this machine.

RDIF scanner included – the machine can store pattern barcode, so it’s easy to choose the pattern you want to use.

Y Direction: 950MM

X Direction: 1400mm Standard -- No Limitation (Can be extended using table extensions)

Lubrication Type: Dryhead Technology (No Oil Required)

Max Sewing Speed: 2800RPM

Hook Size: Big Hook (L)

Built-In Memory: Stores 999 Patterns

Stitch Length: 0,1 mm – 12,7 mm

Clamp Lifting Clearance: up to 16 mm

Open Frame: 1400 x 950 mm is included

Needle system: DP×17

For automatic multidirectional sewing use SCHMETZ needles in MR or SERV 7 version, with correct needle points, depending on the fabric.

We provide custom clamps for every application as well as programming the machine to run specific jobs. Our engineering team is available to customize the machine to accomodate for your special sewing applications. For advanced operation, we can also deploy and maintain on-demand computer systems which enable to remotely configure designs and operate the machine.

If you're interested in customized solutions with this machine, please reach out to us via phone at +1 (727) 335-3434 or via email at info@jacksew.com for more information on the pricing.

Jacksew offers nationwide on-site installation and training services. Please contact us for a quote.

Jacksew offers extensive financing options thru banking partner with funding as soon as 72 hours. Reach out to us via phone at +1 (727) 335-3434 or via email at info@jacksew.com for more information on financing.

Besides any applicable warranties provided by the Original Manufacturer, Jacksew offers a standalone 90-day limited warranty on defects in materials and workmanship.

This warranty covers all the machine parts and labor but any shipping costs must be covered by the customer

Only applies under normal sewing conditions as prescribed for the machine

Consumable items are not covered (needles, bobbins, bobbin cases, springs, oil, and belts)

This warranty does not cover improper use or abuse under heavy use of machines

This warranty does not cover flood, fire, or other acts of nature

If there are any warranty issues that arise, we ask that you contact us immediately and let us know the details. In most cases, we can guide you with getting your machine in good sewing condition via phone, text or video chat.

If you need any parts that need to be replaced, we stock the majority of parts for immediate shipment. Some parts not in stock may have to be ordered from the manufacturer and may take 1 to 2 weeks for arrival.

If there is a critical issue that needs to be addressed and is out of scope of minor adjustments or repairs, we will ask you to send us the machine to our shop so we can have it repaired and have it back to good sewing condition. In most cases, we will only need the machine head shipped to us. Shipping charges - both inbound and outbound - are the responsibility of the customer.

Warranty issues do not arise frequently because of our commitment to assemble, test and verify each machine we ship out to our customers. We will never send you a machine directly from the manufacturer in boxes without knowing that the machine will be ready to operate upon arrival.

DISCLAIMER: DUE TO THE HEAVY WEIGHT AND SHIPPING METHODS USED FOR INDUSTRIAL MACHINES THEY MAY EXPERIENCE MARRING AND SCRATCHES DURING SHIPPING. THIS WILL NOT AFFECT THE OPERATION OF THE MACHINE.

ANY DAMAGE OCCURRING DURING SHIPPING MUST BE CLAIMED TO THE FREIGHT CARRIER IMMEDIATELY. UPON REQUEST, JACKSEW WILL PROVIDE ASSISTANCE IN FILING A CLAIM ON YOUR BEHALF DURING SUCH AN EVENT. PLEASE NOTIFY US WITHIN 5 BUSINESS DAYS.