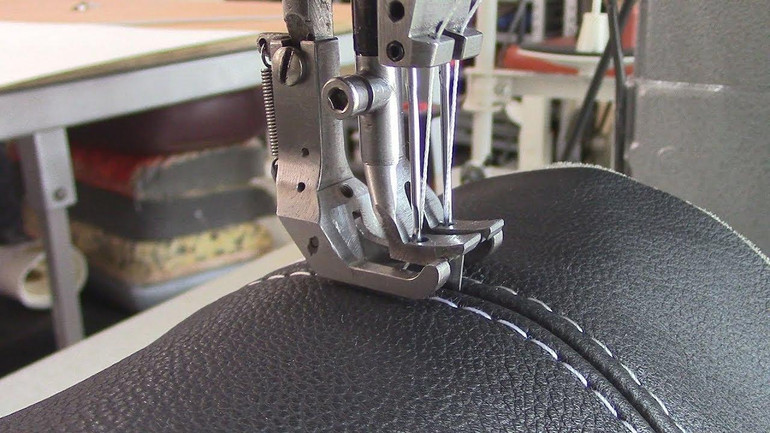

When it comes to upholstery work, harnessing the power of industrial sewing machines is key to achieving exceptional results. These robust and feature-rich machines are designed to handle the demanding nature of upholstery projects with precision and efficiency. In this article, we will explore some of the top industrial sewing machine brands and models renowned for their prowess in the upholstery realm. By delving into their technical specifications and capabilities, we aim to empower you to make an informed decision when selecting the perfect machine for your upholstery endeavors.

The world of sewing machines can be a source of confusion. Many frequently asked questions revolve around the necessity of sewing skills, the need for specialized machines, and the process of choosing the right sewing machine for upholstery projects. Today, we will unravel the secrets of what makes a great upholstery sewing machine, ensuring you make an informed decision based on your unique needs.

The good news is that sewing skills are not a prerequisite for upholstery! There are plenty of projects that require little to no sewing. If you're interested in exploring no-sew upholstery projects, we recommend checking out a blog dedicated to this creative approach.

While a domestic sewing machine suffices for many upholstery projects, as your skills progress, you may want to venture into larger or more advanced endeavors. Having a dedicated sewing machine for specific projects can greatly enhance your experience and ease the process.

When comparing domestic and industrial sewing machines, there are some commonalities but also significant differences in their handling and functionality.

Stitch Options:

Domestic sewing machines offer a wide array of stitch options that you won't typically find in industrial machines used for upholstery. However, for upholstery purposes, these additional stitch options are often unnecessary. A straight stitch capability is usually sufficient for furniture upholstery.

Speed:

Domestic sewing machines are designed for home use, where high-volume production is not expected. However, if you plan to turn upholstery into a business and increase your production while maintaining superior quality, industrial sewing machines are the way to go. These machines can handle more durable and thicker fabrics, and their stitches are stronger. The motors in industrial models are built for constant use, allowing for faster sewing speeds and a heavy-duty workload.

Fabrics:

While domestic sewing machines excel in various projects, they can struggle with thicker or heavier fabrics and specific tasks like sewing cushions. Industrial sewing machines, especially those with a walking foot mechanism, offer the capability to handle a wide range of fabrics, including chenilles, velvets, leather, and larger projects.

Now, let's focus on the must-haves when considering an upholstery sewing machine.

Ability to handle heavier weight fabrics for regular use.

Compatibility with upholstery threads, such as 69-bonded nylon, which may not be supported by all domestic sewing machines.

A servo motor, providing speed control with adjustable settings. This feature allows for both slower precision sewing and faster speeds to increase productivity over time.

In the long run, investing in an industrial sewing machine is often worth it, despite the slightly higher cost compared to basic domestic models. Industrial machines are better suited for heavy-weight upholstery fabrics that require sewing. For instance, an industrial walking foot sewing machine can be a game changer when working on projects like sewing cushions.

Here are some of most commonly used sewing machines for upholstery:

Juki DNU-1541 Series:

The Juki DNU-1541 series has gained acclaim for its exceptional performance in upholstery applications. This walking foot, single-needle machine boasts a high presser foot lift, allowing for easy maneuvering of thick fabrics and multiple layers. With a maximum sewing speed of 2,500 stitches per minute and a large bobbin capacity, the DNU-1541 series ensures efficient and uninterrupted sewing. Its heavy-duty construction, coupled with adjustable stitch length and foot pressure, offers precise and reliable stitching results, making it a top choice for upholstery professionals.

Consew 206RB-5:

The Consew 206RB-5 is another formidable contender in the upholstery sewing machine market. With its walking foot mechanism, large vertical axis hook, and high sewing speed of up to 3,300 stitches per minute, this machine tackles heavyweight materials effortlessly. Its compound feed system ensures smooth and even feeding, minimizing fabric slippage or puckering. The 206RB-5's adjustable stitch length and reverse stitching capability provide further control and versatility, making it an ideal choice for upholstery projects of various complexities.

Durkopp Adler 267:

The Adler 267 sewing machine series is renowned for its robust construction and reliability. Equipped with a compound feed system, this single-needle, walking foot machine excels in handling heavy and dense upholstery fabrics. With its powerful motor and maximum sewing speed of 2,000 stitches per minute, the Adler 267 ensures efficient and consistent performance. This model also offers adjustable stitch length, foot pressure, and reverse stitching, providing precision and flexibility for upholstery tasks of all scales.

Durkopp Adler 669:

The Durkopp Adler 669 series is an exemplary choice for upholstery professionals seeking advanced technology and high-end features. With its triple feeding system, this machine effortlessly handles challenging materials, ensuring flawless stitch formation. The 669 series offers a wide range of stitch patterns, including decorative stitches and bartacking, allowing for enhanced creative expression. Its programmable touch screen interface provides intuitive control and customization options, making it an excellent investment for those seeking cutting-edge technology in upholstery sewing.

Pfaff 1245:

The Pfaff 1245 is a heavyweight champion among upholstery sewing machines. This flatbed, single-needle lockstitch machine boasts remarkable precision and durability. With a maximum sewing speed of 3,000 stitches per minute, the Pfaff 1245 effortlessly sews through layers of upholstery fabric, delivering impeccable results. Its integrated walking foot mechanism ensures optimal fabric feeding, while features like adjustable presser foot pressure and stitch length offer versatility and control. The Pfaff 1245's robust construction and renowned German engineering make it a reliable choice for upholstery professionals seeking longevity and performance.

As you delve into the world of industrial sewing machines for upholstery, familiarizing yourself with top brands and models empowers you to make an informed decision. The Juki DNU-1541 series, Consew 206RB-5, Adler 267, Durkopp Adler 669, and Pfaff 1245 are just a few examples of exceptional machines that have proven their mettle in the upholstery realm. With their technical prowess, robust construction, and specialized features, these machines allow you to tackle upholstery projects of all complexities with confidence and precision. So, choose a brand and model that aligns with your specific requirements, and unlock the true potential of industrial sewing machines in your upholstery endeavors.

Canadian Dollar

Canadian Dollar