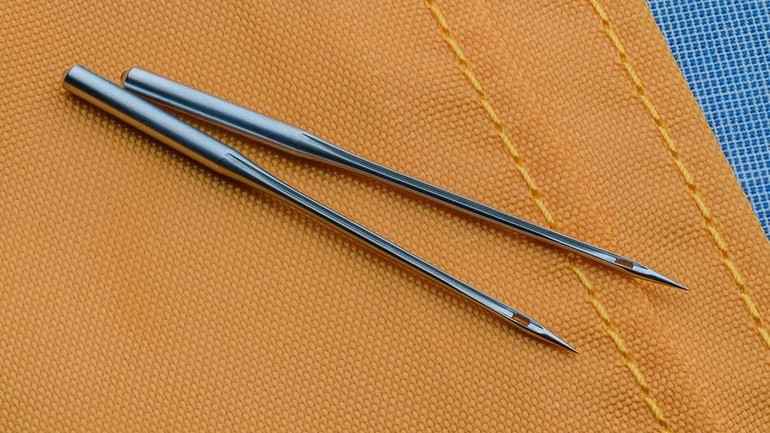

In industrial sewing, the choice of needle is as crucial as the machine itself. Different fabrics and sewing tasks require specific types of needles to ensure optimal results. Understanding the various kinds of industrial sewing machine needles and their appropriate use cases is essential for any professional in the textile industry.

Types of Industrial Sewing Machine Needles

- Universal Needles: These are the all-rounders of the sewing world. Ideal for a variety of woven and knit fabrics, they have a slightly rounded point that is versatile enough for numerous applications.

- Ball Point Needles: Designed specifically for knit fabrics, ball point needles have a rounded tip that allows them to pass between fabric fibers rather than piercing them. This prevents damage to the fabric structure, making them perfect for materials like jersey, spandex, and other stretchy fabrics.

- Sharp Needles: Also known as Microtex needles, they have a very sharp point and are ideal for finely woven fabrics. They're the go-to for silks, microfiber, and other lightweight fabrics where precision and a clean stitch are necessary.

- Leather Needles: These needles come with a chisel point (wedge point) designed to penetrate tough materials like leather, suede, and vinyl without tearing them. They are essential for any work involving these heavy, non-woven materials.

- Denim Needles: Specially made for sewing through multiple layers of dense fabrics, denim needles are stronger than universal needles and have a sharper point. They are perfect for jeans, canvas, and similar heavy woven fabrics.

- Embroidery Needles: These needles have a larger eye to accommodate thicker embroidery threads. They're designed to prevent shredding or breakage of these threads during high-speed embroidery work.

Choosing the Right Needle: Use-Case Scenarios

- For Standard Garments: Universal needles are usually sufficient for most standard fabrics used in garment manufacturing.

- For Stretch Fabrics: When working with stretch fabrics like Lycra or knitted materials, ball point needles are the best choice to avoid skipped stitches and fabric damage.

- For Fine and Delicate Fabrics: Use sharp needles for fabrics like silk or chiffon to ensure clean, straight stitches without harming the fabric.

- For Leather Products: Always opt for leather needles when working with leather goods to ensure the needle can penetrate the material without causing tears or rough stitches.

- For Heavy-Duty Sewing: In the case of heavy materials like denim or canvas, denim needles are ideal as they can handle the thickness and density without breaking.

- For Embroidery Work: When dealing with embroidery, especially at an industrial scale, choose embroidery needles to accommodate specialty threads and high-speed sewing.

Selecting the right needle for your industrial sewing machine is critical to achieving the desired results. Whether dealing with delicate silks, stretchy knits, or tough leathers, the correct needle not only makes the sewing process smoother but also ensures the integrity and quality of the final product. Understanding the specifics of each needle type is a valuable skill for any textile professional, paving the way for superior craftsmanship in every sewing endeavor.

Canadian Dollar

Canadian Dollar